GLASS COATED MICROWIRES

(GENERAL INFORMATION)

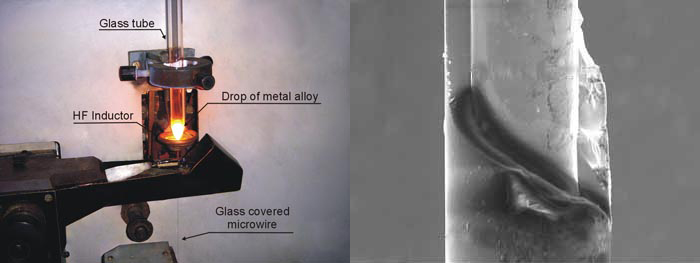

Microwires are manufactured by means of a modified Taylor-Ulitovsky process [1-5] based on direct casting from the melt, as it is schematically depicted in Fig. 1. In the laboratory process, a few grams of the master alloy with the desired composition is put into a glass tube and placed inside the work coil of a high frequency induction heater. The alloy is heated up to its melting point, forming a droplet. While the metal melts, the portion of the glass tube adjacent to the molten metal softens, “enveloping” the metal droplet. A glass capillary is then drawn from the softened glass portion and is further wound on a rotating bobbin. At suitable drawing conditions, the molten metal fills the glass capillary, and a microwire is thus formed with its metal core being completely coated by a glass shell. The amount of glass used in the process is balanced by continuous feeding of the glass tube to the induction heating zone, whereas the formation of the metallic core is restricted by the initial quantity of the master alloy droplet. The microstructure of a microwire (and hence, its properties) depends substantially on the cooling rate, which can be controlled by a cooling unit where the metal-filled capillary passes through a jet of cooling liquid (water or oil) on its way to the receiving coil.

The main advantages of this method of microwire fabrication are:

- sustainability of microwire properties in mass-production;

- wide range of parameters variation (both geometrical and physical);

- production of continuous long pieces of microwire, up to 10 000 m on the delivery spool;

- online control and monitoring of geometrical parameters (inner core diameter and glass thickness) during the production process

Literature:

G.F. Taylor G.F., Phys. Rev., 23, (1924) pp.655-660,

G.F. Taylor, Process and apparatus for making Filaments, Patented Feb. 24, 1931, United States Patent Office, 1, 793, 529.

A.V. Ulitovsky, in "Micro-technology in design of electric devices", Leningrad, 1951, No.7, p.6.

A.V. Ulitovski and N.M. Avernin, "Method of fabrication of metallic microwire" Patent No161325 (USSR), 19.03.64. Bulletin No7, p.14 5. A.V.Ulitovsky, I.M. Maianski, A.I. Avramenco, "Method of continuous casting of glass coated microwire" Patent No128427 (USSR), 15.05.60. Bulletin. No10, p.14